Benson Energy Saving Technology Production Process Introduction

The R&D group of Benson Energy Saving Technology consists of professional LED lighting engineers and designers with many years’ experiences in the LED lighting field. We dedicate all the time, dedication, and innovation to study and analyze every case and make sure all our LED lighting products are certified and qualified in the lighting market and to advance with the times by using sophisticated instruments for accurate measurement.

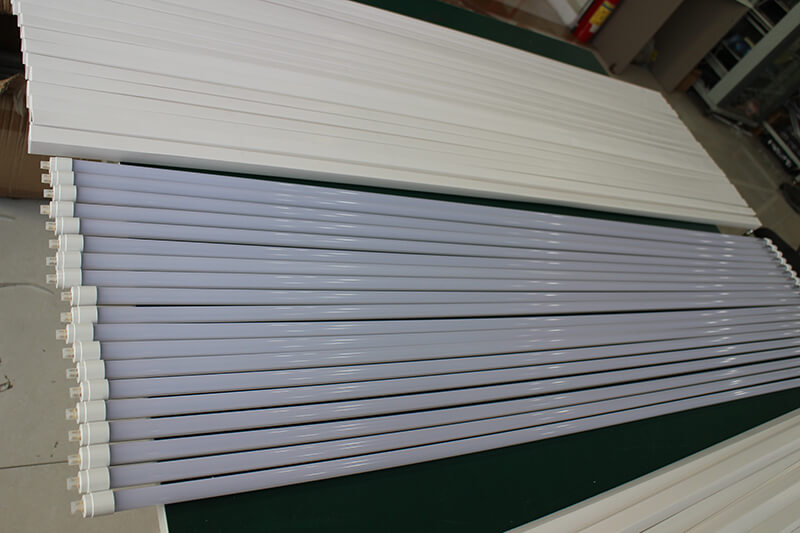

BEST has the modern manufacturing plant covering 8000 square meters, and having more than 100 skilled workers.

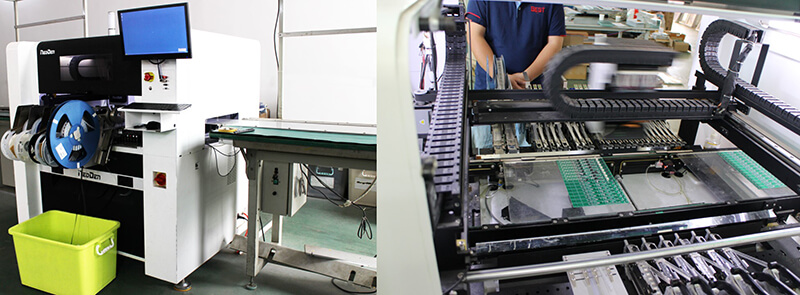

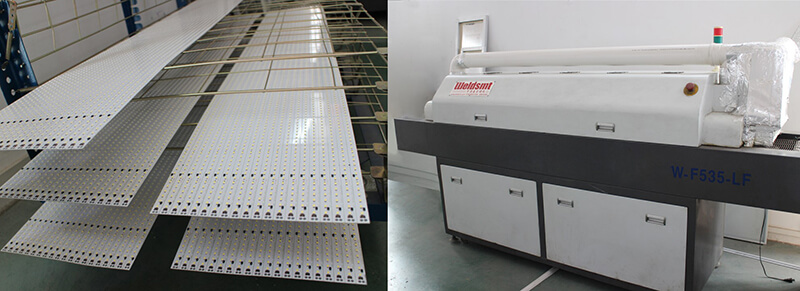

Equipment:

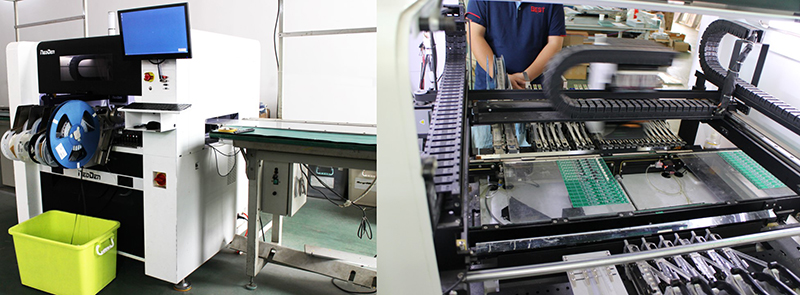

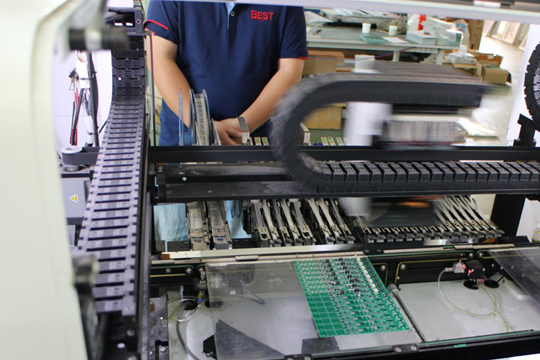

- Automatic SMT machines

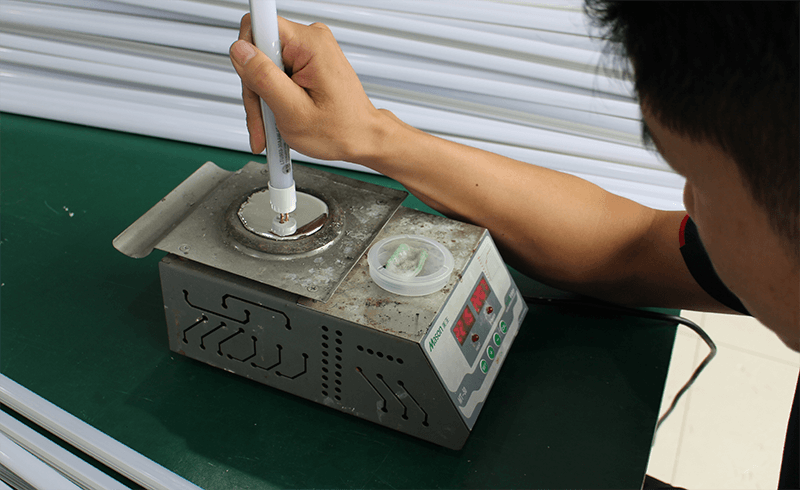

- IES testing system

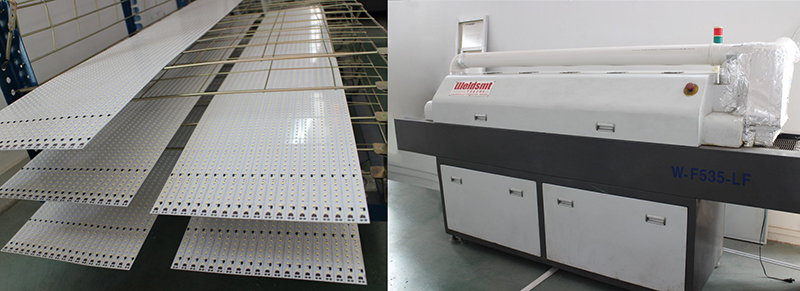

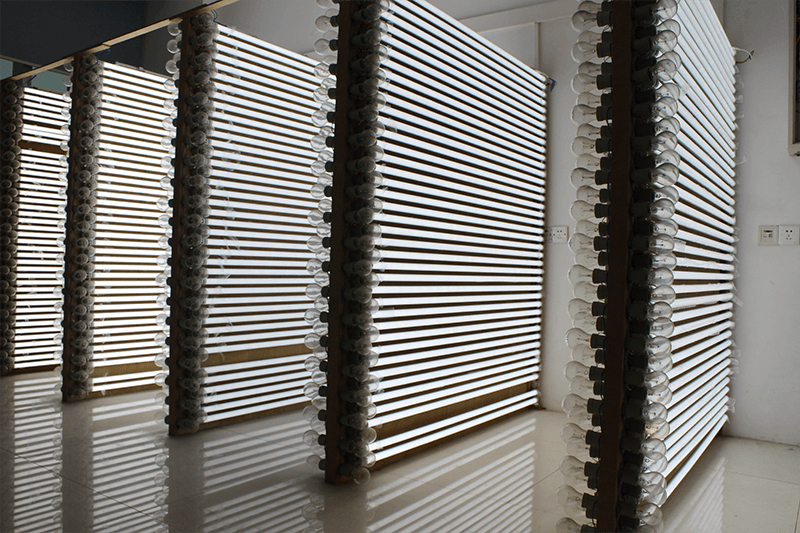

- Automatic aging lines

- Laboratory

Monthly production Capacity: Above 300,000 pieces of LED products. We have built-up long-term business relationships with many customers around the world.

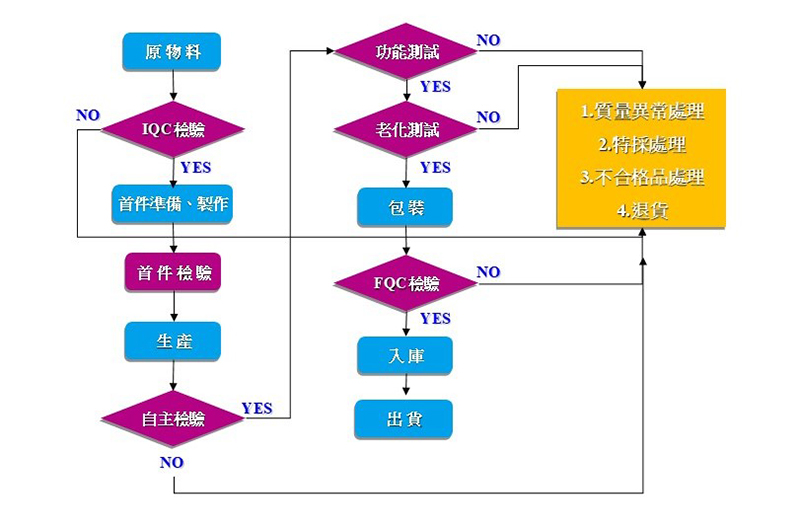

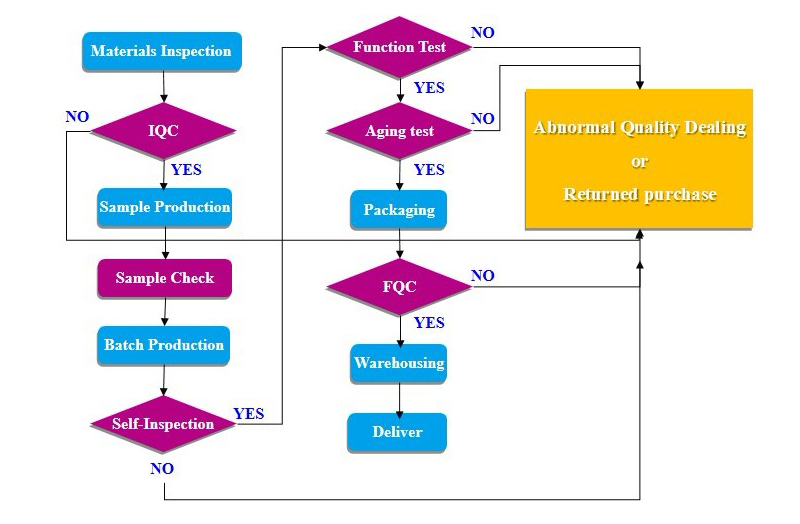

A) IQC Inspection

B) SMT Production Line

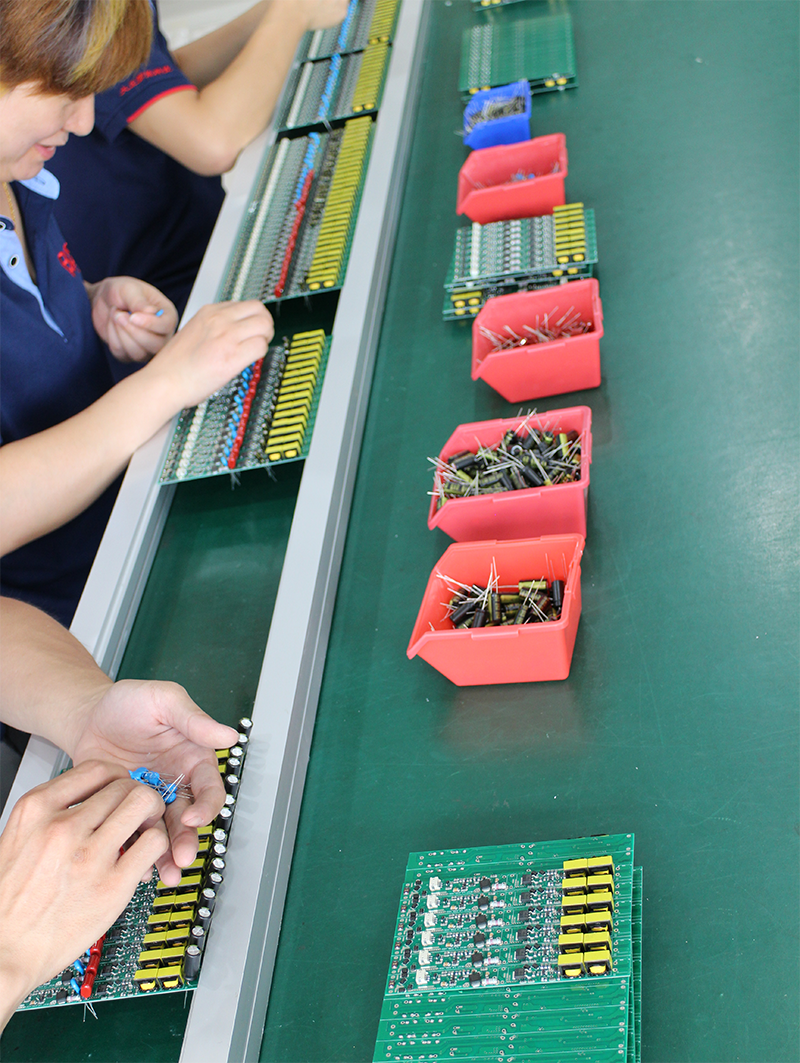

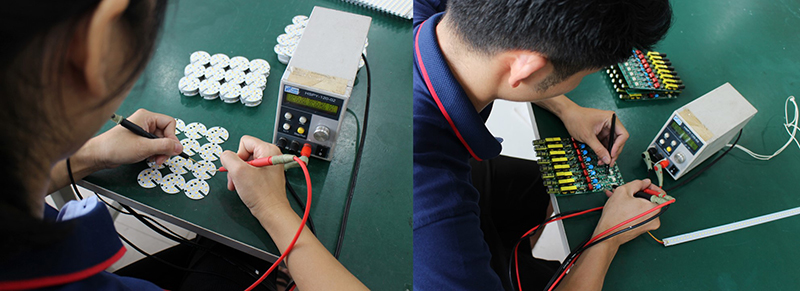

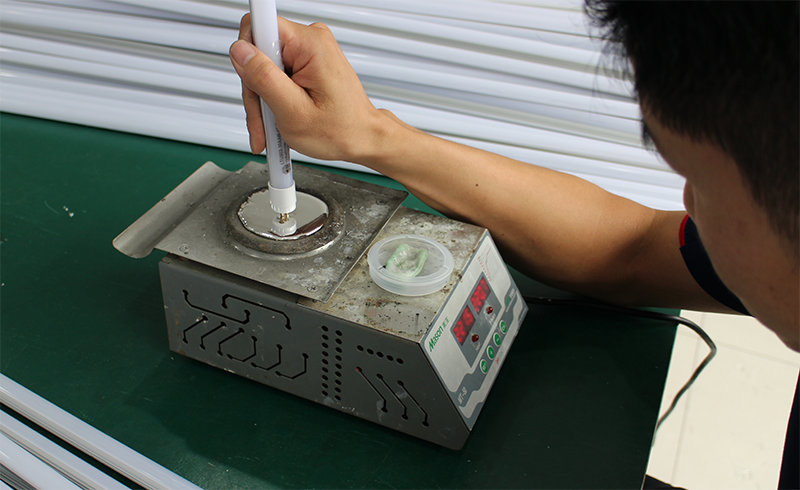

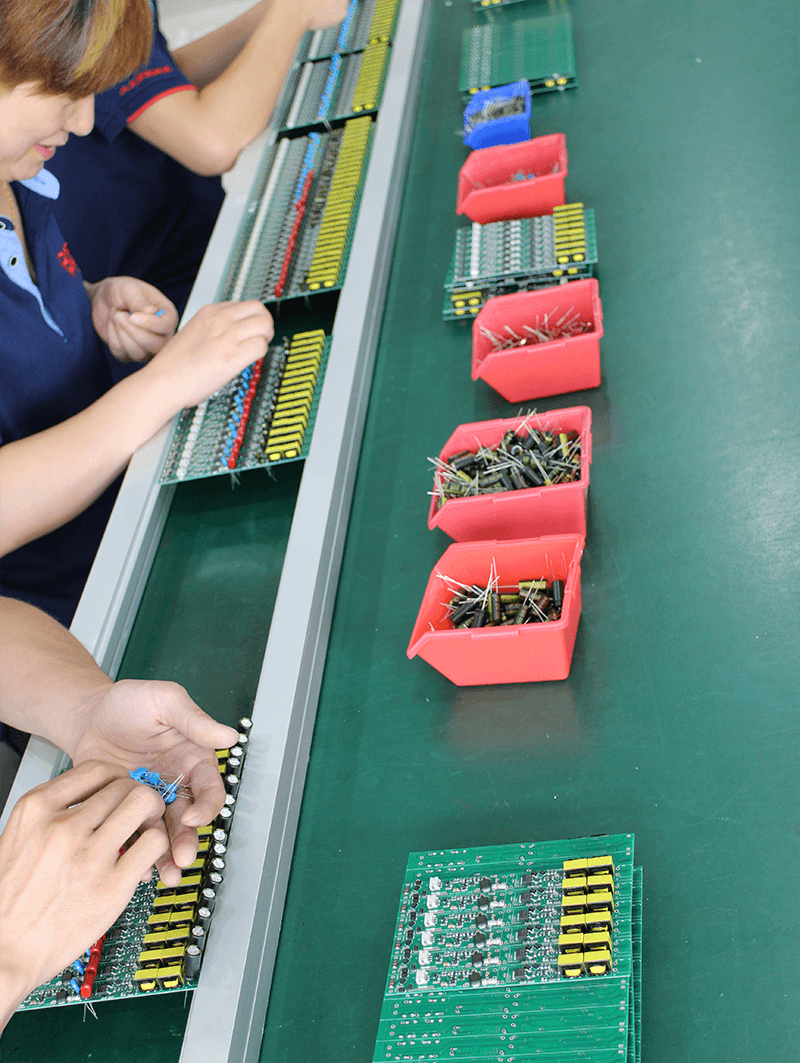

C) Inspection & Assemble

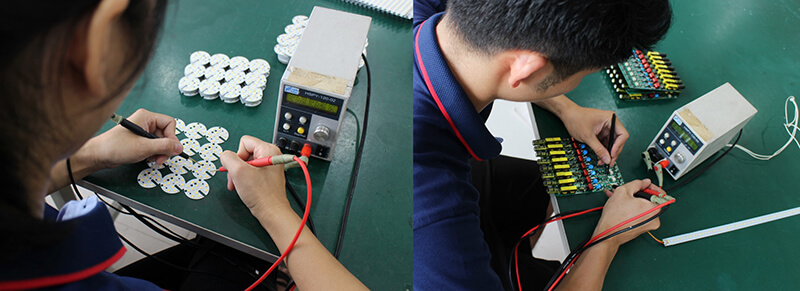

D) QC Inspection (Including IES Testing)

E) Packaging