Why yellow light tubes are using in cleanroom of semiconductor industry?

What is photolithography?

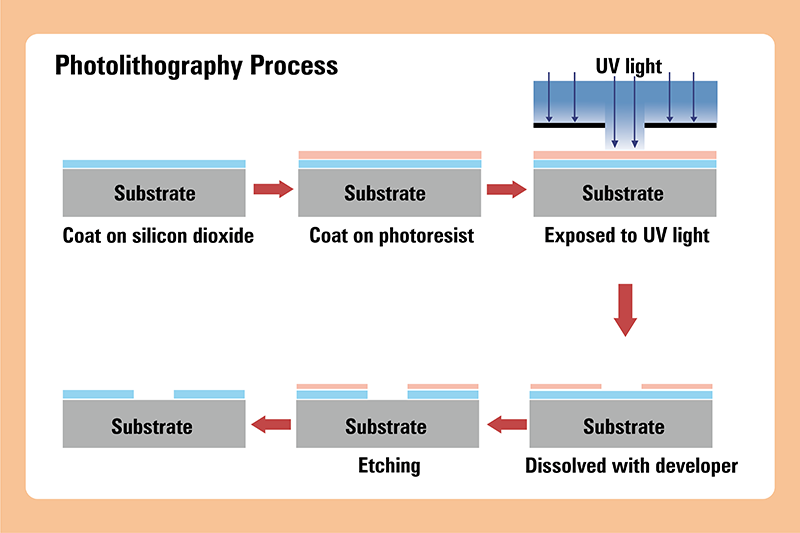

Photolithography is one of the important processes in the production of integrated circuits (ICs or chips). Simply say, it is the process of copying a circuit pattern on a substrate by using the photomask and photoresist.

The substrate will be painted on silicon dioxide insulating layer and photoresist. The photoresist can be dissolved easily with a developer after being exposed to UV light, after dissolver and etched, the circuit pattern will be left on the substrate.

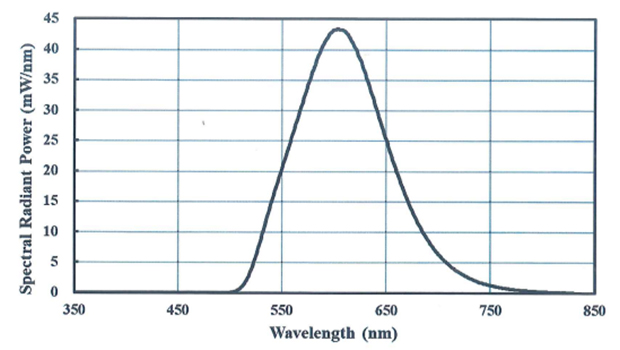

What is Photoresist? Why must 500nm UV wavelength blocks-off?

Photoresist is combined with resins, solvents and additives. The light sensitive range of photoresist is 200nm-500nm. Therefore, many semiconductors laboratory will adopt yellow light which blocks off 500nm UV wavelength to prevent the photoresist overexposed or prematurely exposed situations.

BEST’s special T8 LED retrofit LED tubes are specially designed for semiconductor laboratories and lithography. Industrial Technology Research Institute in Taiwan has proved that the BEST’s T8 LED yellow tube can filter 500nm UV wavelength so that the photoresist will not be affected by surrounded lighting factors.

Do you know BEST’S special T8 yellow LED tubes can be also used in these industries?

Such as Integrated circuits, panel displays, museums, libraries, printing industry, lithography laboratories and other places with photosensitive element materials, etc.

Photolithography No UV T8 4F yellow LED tube introduction:

- Directly replace old T8 fluorescent tubes, reusing old fixture.

- UV protections,block off UV wavelength under 500nm.

- Stable quality with over heat, over current and short circuit protection.

- 30,000 hours life span, over 15,000 times switching cycles.

- Aluminum & PC material, mercury-free.

- CE, RoHS certifications and proved by national laboratory spectrum report.

- Applications: semiconductor factory, semiconductor laboratory, clean room, museum, library, printing house, photolithography laboratory or other UV-sensitive areas.

- We also support clean room luminaire such as paint booth light, teardrop luminaire, T-bar ceiling luminaire for your reference.

↑National laboratory spectrum report of T8 LED yellow tube.

You can find the measurement report from Industrial Technology Research Institute in Taiwan here in the below link:

Photolithography No UV T8 4F yellow LED tube report:

https://www.best-energysaving-tech.com/de/news/N2022033100001/news_detail.html

Clean room luminaire catalogue:

https://www.best-energysaving-tech.com/de/news/N2022030100001/news_detail.html

Who are we?

Benson Energy Saving Technology is a professional LED manufacturer with over 10 years’ experience in lighting and electronic filed. Export to Europe area with the highest quality. We also offers lighting product OEM and ODM service.

Following the concept of eco-friendly, BEST uniquely developed electronic ballasts compatible LED lighting technology. With five-country patent certifications, breaking through the limitations of LED lighting technology and leading the world to the next LED lighting industry generations.

Our LED series products are all conform to circular economy concept, highly upgrade the energy efficiency of LED products, which is the BEST choose for green enterprise.